SERIES

Bend series

Tee series

Flange series

Reducer series

Simmer the bent pipe ser

Wear-resistant pipe fi

Plant accessories series

Ripple compensator seri

Pipe expander

Cleaner series

Piping support series

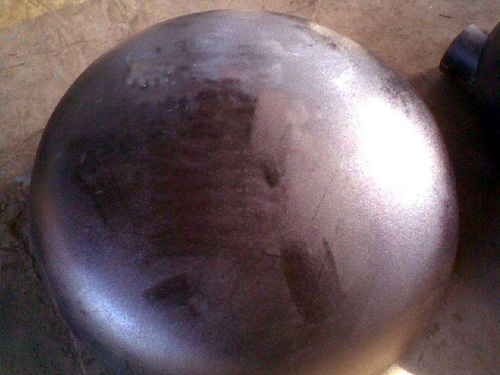

Head cap

Pipe series

Insulation series

Series of anti-corrosion

Concrete pump accessories seri

Plastic Lined Pipe Series

Surfacing machine / wire drawi

head

A type of boiler in a pressure vessel, usually used at both ends of the pressure vessel. Then there is a welding tube product that seals at the end of the pipe. There are many forms.

The header is a part of the container that is welded to the cylinder. (pictured), according to the geometry of the different can be divided into spherical or oval, dish, QiuGuanXing, conical shell cover and so on several kinds of peace, spherical and elliptic type, disc, ball crown head is referred to as convex head. The welding is divided into welding heads and socket welding heads. Used for various container equipment, such as tank, heat exchanger, tower, reaction kettle, boiler and separation equipment. The material is made of carbon steel (A3, 20 #, Q235, Q235, Q345B, 16Mn, etc.), stainless steel (304, 321, 304L, 316, 316L, etc.), alloy steel (15Mo3 15CrMoV 35CrMoV 45CrMo), aluminum, titanium, copper, nickel and nickel alloy etc.

End use:

The sealing head is an indispensable part in the pressure vessel equipment in many industries of petrochemical, atomic energy and food industry.

The sealing head is the end cover of the pressure vessel, which is a main pressure component of the pressure vessel. The effect is to seal. One is to make the bottom and bottom of the tank pressure vessel, and the second is the end of the pipe, which is not ready to go any further, and seal the pipe with a seal in the form of welding. Products with a similar effect are blind and tube caps, but those two products can be disassembled. When the head is welded, it is not allowed to disassemble. There are pressure vessels, pipes, flanges, elbows, tee, and four - pass products.

The quality of the head is directly related to the long-term safe and reliable operation of the pressure vessel.

Cover head basic requirements:

Our country existing standard of head, is according to the structure (oval, dish and cone), forming, stamping, spinning, and respectively, which not only cause different standard head quality requirement is not completely consistent with the unreasonable phenomenon, but also to the revision of the standard selection of head, bring certain difficulties.

One's head, ever Are only and GB150 "steel pressure vessel" matching, which only considers the design of the head according to rule of fabrication, inspection and test requirements, and our country as early as 1995 GB150 and JB4732 the foundation pressure vessel standards of double-track (with "steel pressure vessel analysis design standard"), a lack of analysis and design matching with the standard of head, is a major drawback of the pressure vessel standardization work in China.

GB150 belongs to the compulsory standards, and according to GB150 establishment and come to match the head set with the standard is a guidance (recommended), it is obviously unreasonable, head is difficult to guarantee the quality of the compression of the important components.