SERIES

Bend series

Tee series

Flange series

Reducer series

Simmer the bent pipe ser

Wear-resistant pipe fi

Plant accessories series

Ripple compensator seri

Pipe expander

Cleaner series

Piping support series

Head cap

Pipe series

Insulation series

Series of anti-corrosion

Concrete pump accessories seri

Plastic Lined Pipe Series

Surfacing machine / wire drawi

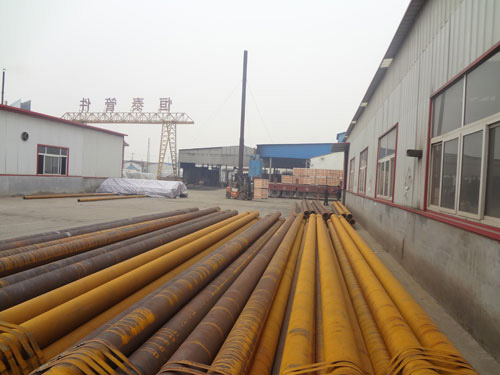

Seamless steel pipe

Seamless steel tube is a kind of circular, square, rectangular steel with hollow section and no seams. The seamless steel tube is made of steel ingot or solid tube billet through perforation, and then hot rolled, cold rolled or cold made.

Seamless steel pipe is hollow section, a large number of used for conveying fluid pipe, steel pipe and round steel, compared to solid steel in the bending torsional strength phase at the same time, the weight is lighter, is a kind of economic cross section steel, widely used in the manufacture of structural and mechanical parts, such as petroleum drill pipe, auto transmission shaft, bicycle frame and construction of steel scaffolding is used.

Seamless steel pipe for low carbon steel pipe, carbon steel is generally divided into low carbon steel, medium carbon steel and high carbon steel, which is suitable for medium carbon steel 45 # steel, 45 # is lower than low carbon steel, 45 # is higher than high carbon steel, seamless steel pipe, such as no special requirements, generally adopt # 20 seamless steel tube.

Seamless steel tube material is 20# steel, the strength is higher than 15 #, rarely quenched, no temper brittleness. Cold deformation of high plasticity, commonly used for bending, rolling, flanging and hammer processing, such as arch arc welding and resistance welding welding performance is good, when welding thickness is small, strict shape or complex shape parts prone to crack. Machinability cold drawing or positive fire condition is good, generally used for manufacturing workpiece with low stress and high toughness.

General seamless steel tube production process can be divided into cold drawing and hot rolled, cold rolled seamless steel tube production process generally more complicated than hot rolled, three-roll rolling tube billet must first, after the extrusion sizing test, if there is no response after crack on the surface of pipe have to be cut after cutting machine, cutting grow about a meter of billet. And then enter the annealing process, annealing with acid pickling liquid, pickling when should pay attention to whether there is a lot of bubble surface, if there is a lot of bubbles show that the quality of the steel tube can not meet the corresponding standards. Appearance on cold rolled seamless steel tube is shorter in hot rolled seamless steel pipe, cold rolled seamless steel tube wall thickness generally smaller than hot rolled seamless steel tube, but the surface looks brighter than the thick wall seamless steel tube, not a lot of rough surface, the diameter is not a lot of burr.

Production process of seamless steel tube:

1, cold drawing (rolling) seamless steel tube, round tube, heating to punch to heading, annealing, pickling and oil (copper) and multichannel time cold drawing (cold rolled) to the tube billet - heat treatment - straightening, quality wall thickness to hydrostatic test (NDT) - > tag, put in storage.

2, hot rolling (extrusion seamless steel tube) : the circular tube billet - heat - punch - three-roll skew rolling, rolling, or pressing - to take off the tube and sizing (or reducing) - cooling - the tube billet - straightening - quality wall thickness to hydrostatic test or inspection - > tag, put in storage.