SERIES

Bend series

Tee series

Flange series

Reducer series

Simmer the bent pipe ser

Wear-resistant pipe fi

Plant accessories series

Ripple compensator seri

Pipe expander

Cleaner series

Piping support series

Head cap

Pipe series

Insulation series

Series of anti-corrosion

Concrete pump accessories seri

Plastic Lined Pipe Series

Surfacing machine / wire drawi

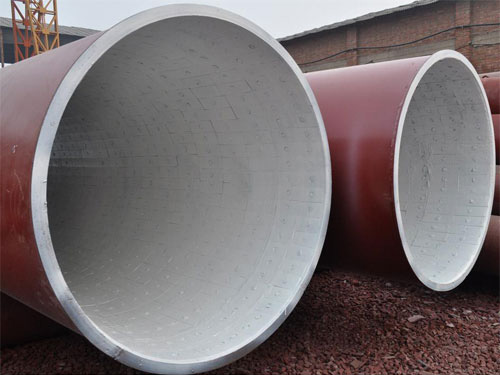

Ceramic patch wear-resistant pipeline

Wear-resistant ceramic tiles is AL2O3 as raw materials, rare metal oxides as solvent, through the high temperature of 1600 ℃ sintering of special alumina ceramic, again USES the wear resistant, wear resistant ceramic tiles adhesive can choose wear-resisting ceramics tiles according to different needs, meet customer demand for special technical conditions. Wear-resistant ceramic patch is 280 times the wear resistance of manganese steel and 180.5 times of high chromium cast iron. It is widely used in power plant coal powder conveying, steel plant sintering dedusting, cement plant and other related equipment, pipelines.

Performance of the ceramic patch wear-resistant pipeline:

1, abrasion resistance, ceramic composite steel pipe lined with porcelain layer of Al2O3 content is more than 90%, micro hardness HV1000-1600, 3.8 3.97 g/cm3 density, thus has high wear resistance, its wear resistance is higher than the medium carbon steel after quenching ten times, is better than that of tungsten carbide drill.

2, the corrosion resistance of ceramics is a neutral material, stable chemical performance, excellent corrosion resistance and acid resistance, can resist various inorganic acid, organic acid, organic solvents, such as its resistance to corrosion is stainless steel is more than ten times.

3, heat resistant ceramic layer dense corundum, the linear expansion coefficient is 6-8 x 10-6 / ℃. Heat resistant performance, can heat resistance above 2000 ℃, can in - 50 ℃ ~ 900 ℃ within the scope of work for a long time.

4. Mechanical properties: with excellent mechanical properties, the crushing strength of 300 to 600MPa, the pressure shear strength of 20-30mpa, the anti-mechanical shock test was 15 times without obvious cracks under the impact of 50t energy.

5. Easy to weld: the ceramic lining composite steel tube can be connected by welding the outer tube.

6. Convenient transportation and installation: the ceramic lining composite steel tube is relatively lightweight and easy to transport and installed compared with steel pipe, abrasion resistant alloy cast pipe, cast iron pipe and cast stone tube. Ceramic lining composite steel pipe can be used for welding, flanges, flexible quick joints, etc., and installation is very convenient.

The ceramic patch wear-resistant pipeline can be used in many kinds of pipelines of heat and power, steel, non-ferrous metals, mines, coal, chemical and petrochemical industries.

1. Require high wear-resisting pipes: coal and ash (slag) conveying pipes of thermal power plants, tailings and concentrates conveying pipes of concentrator, port and sediment transport pipelines, and pulverized coal slurry pipeline, etc.

2. Require highly corrosive types of pipes.

3. Molten aluminium liquid transport pipeline.

4. High wear resistance, high corrosion resistance and high temperature resistance. Economic benefits: used for wear resistant pipe, ceramic lined steel pipe compared with wear-resistant alloy cast iron pipe and cast stone, due to the unit length of the light weight make a hanger to reduce cost, handling cost and installation cost, reduce the project cost.

2. The design and manufacture of pneumatic conveying system, based on the Australian pneumatic conveying technology, its obvious advantage is high starting point, advanced technology, unique and systematic and professional.

3. Double gate high wear resistance ceramic valve (10 times longer than normal valve in pneumatic conveying).

Ceramic veneer wear-resistant pipeline transport material contraindication is liquid, general delivery medium is powdery, granular, wet ash powder can also. The general use industry is: power plant coal powder, ash, mine mineral powder, tailings, back packing, coal mine, concentrator coal, coke granule, burning plant materials and so on.